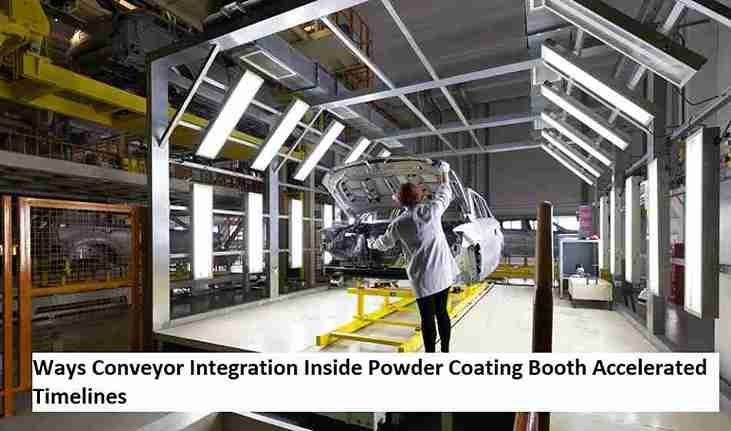

Efficiency inside a finishing line is rarely accidental. Behind the smooth flow of coated parts lies careful planning, and conveyors integrated into an industrial paint booth often provide the hidden advantage. By controlling speed, spacing, and consistency, these systems transform how quickly and reliably work is completed inside a powder coating booth.

Continuous Part Movement That Reduces Idle Time in Coating Booths

Idle parts create wasted minutes, and wasted minutes quickly multiply across a production line. A conveyor that keeps parts in constant motion eliminates gaps between cycles, allowing the coating team to apply finishes without stop-and-go delays. Inside a powder coating booth, this steady rhythm ensures that operators stay focused on applying coatings, not waiting for the next rack or frame to arrive.

The difference becomes even more apparent in larger facilities. Instead of pausing between each run, integrated conveyors move items through an industrial paint booth like clockwork. This uninterrupted sequence shortens overall coating times while keeping operators in sync with the line’s pace, effectively removing unnecessary downtime from the workflow.

Streamlined Transfer Between Spray Zones and Cure Ovens

A common bottleneck occurs at the transition point between spraying and curing. Without conveyors, staff must manually reposition racks, which adds delays and risks damaging freshly coated surfaces. With an integrated system, parts flow smoothly from the spray zone of a powder coating booth into the cure oven, creating a direct path that reduces handling time.

This streamlined transfer not only saves minutes but also protects coating integrity. Surfaces remain untouched until they are fully cured, minimizing rework and rejected pieces. Inside an industrial paint booth setup, this type of system coordination allows production managers to rely on predictable turnaround times from start to finish.

Consistent Line Flow That Keeps Production Schedules on Track

Production schedules demand consistency, and conveyors deliver exactly that. By regulating line flow, each piece spends the right amount of time under the spray guns and moves into curing without unnecessary stalls. The result is a cycle that maintains balance across the entire finishing process.

Inside a powder coating booth, consistent flow prevents overloading at certain stages while leaving other sections idle. A properly integrated conveyor system ensures that the entire finishing line works as one continuous chain, which helps companies meet deadlines without sacrificing coating quality.

Reduced Manual Handling That Cuts Delays in Heavy Cycles

Manual handling may work in small shops, but in high-volume cycles it becomes a time sink. Heavy frames and awkward shapes require teams of workers to reposition, leading to fatigue and slower turnaround. Conveyor systems solve this by carrying the load directly through the industrial paint booth without requiring repeated lifting and shifting.

By reducing reliance on manual labor, these systems protect both the timeline and the workforce. Workers stay safer and fresher, while managers can expect more predictable completion rates during peak demand. Inside a powder coating booth, this automation directly translates into faster and more reliable finishing runs.

Conveyor Systems That Support High Volume Throughput in Booths

Large orders require more than manpower alone—they demand equipment that can handle volume without compromise. Conveyors designed for powder coating booths make it possible to move dozens or even hundreds of pieces through the line each shift, keeping pace with customer expectations.

Industrial paint booth operations benefit from this higher throughput by completing bigger projects in fewer hours. Instead of extending lead times, integrated conveyors expand capacity. This capability allows facilities to scale output upward without expanding floor space or adding excessive labor, making high-volume work both manageable and profitable.

Integrated Motion Control That Keeps Coating Uniform Across Parts

Uniformity is as much about movement as it is about spray technique. Conveyors with motion control maintain steady speeds, ensuring each part receives the same exposure under the spray guns. A sudden stop or inconsistent pace can lead to thin spots or uneven finishes, problems that waste time in rework.

Inside a powder coating booth, motion control eliminates those variables. By moving pieces through at controlled rates, operators gain confidence that coatings will cure evenly and meet quality standards. For industrial paint booth setups, this precision translates into fewer rejects, tighter schedules, and smoother overall operations.

Faster Changeovers Achieved by Coordinated Conveyor Paths

Changeovers between colors or part types often eat up valuable minutes. Coordinated conveyor paths reduce that downtime by directing specific lines or racks to designated areas without stopping the entire system. This built-in flexibility makes it easier to switch projects without bringing the line to a standstill.

For teams working in a powder coating booth, that flexibility can mean the difference between meeting a customer’s deadline or running overtime. Industrial paint booth operations also benefit because conveyor integration keeps multiple shifts running smoothly, even with frequent product changes. The result is less lost time and better adaptability to varied production schedules.

Steady Workpiece Spacing That Maintains Predictable Timelines

Clumping parts together or leaving wide gaps disrupts efficiency. Conveyors that maintain steady workpiece spacing prevent these inconsistencies, keeping the line moving at an even pace. Predictable spacing allows operators to plan their actions with precision, which reduces mistakes and improves coating quality.

Inside a powder coating booth, steady spacing ensures that every item has the proper clearance for coating coverage. In an industrial paint booth, it also reduces the risk of collisions or uneven curing. The end result is a predictable and repeatable process that stays aligned with the production timeline day after day.